Verification

Organizations are moving away from static, siloed approaches toward real-time monitoring, predictive analytics, and scenario-based planning to address complex, interconnected risks.

Leading methodologies include qualitative and quantitative assessments, Failure Mode and Effects Analysis (FMEA), Bowtie analysis, and hybrid models. The future of risk assessment is defined by technological innovation, ethical responsibility, and sustainability.

ISO 12100 presents the fundamental principles and methodologies for machinery safety risk assessment, while ISO 13849 addresses the design and verification requirements to ensure the safety and reliability of machine control systems. Our experts thoroughly apply these two standards to systematically analyze whether our clients' products and equipment comply with global safety standards and to propose improvement measures.

Our services extend beyond simple assessment to include:

Identification of potential hazards in equipment and products

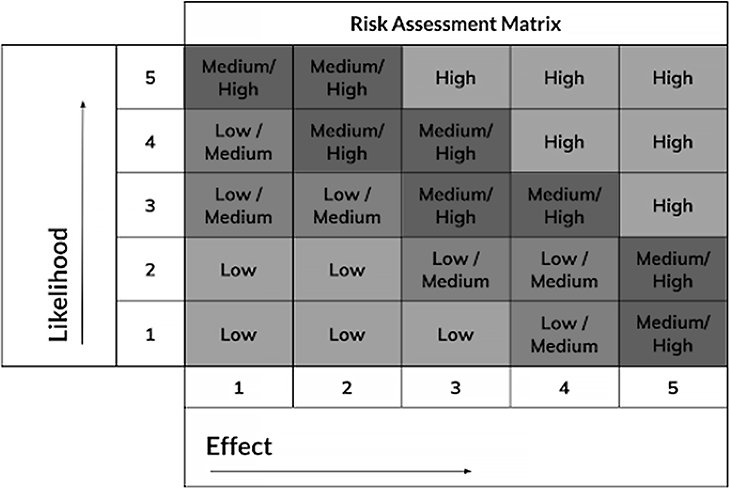

Quantitative and qualitative analysis based on risk frequency and severity

Review of safety-related control system design

Recommendations for improvement and optimization

Globally, Swiss Approval has collaborated with a wide range of plant industries, including EV batteries and materials, on-offshore facilities, oil and gas, renewable energy, and chemicals.

With our knowledge and solutions, our clients are ideally positioned to manage their organizational risk profiles, prepare for emergencies, and safeguard their operations, businesses, and society at large.

Swiss Approval’s Risk Assessment service delivers the following services as a customized way.

● Risk management

Management system risk reduction: HSSEQ (Health, Safety, Security, Environment and Quality)● Risk analysis

Quantitative Risk Analysis (QRA) Risk Analysis (qualitative) Barrier management Emergency preparedness analyses Environmental Risk Analysis Safety Case support Event Tree Analysis Hazard Identification (HAZID) Hazard and Operability (HAZOP) studies Explosion-protection Perform classification of hazardous areas (IECEx CoPC Unit Ex 002)● Reliability & asset performance optimization

Failure modes and effects and criticality analysis (FMECA) Safety integrity level (SIL) assessments Reliability, Availability and Maintainability (RAM) - regularity assessment Asset performance and RCMRisk assessments are crucial for enhancing safety, improving product quality, and ensuring regulatory compliance. By proactively identifying potential hazards and developing mitigation strategies, engineers can prevent accidents, reduce downtime, and optimize project outcomes. This systematic approach also leads to better-informed decision-making, increased stakeholder confidence, and ultimately, more successful and cost-effective projects.

1. Enhanced Safety and Reliability: Accident Prevention: Reduced Downtime: Improved System Reliability

2. Improved Product Quality: Robust Design: Enhanced Usability: Competitive Advantage:

3. Regulatory Compliance and Legal Protection: Meeting Safety Standards: Legal Defense:

4. Cost Reduction and Efficiency: Preventing Costly Accidents: Optimized Resource Allocation: Efficient Processes:

5. Improved Decision-Making: Informed Choices: Prioritizing Actions: Increased Stakeholder Confidence: